Analysis and Improvement

Employees behave in a safety-oriented manner, errors are eliminated and processes run smoothly. We help you to get even closer to this ideal.

We support you in carrying out analyses of the entire spectrum of human, technology and organisations (HTO) – whether as a preliminary HTO analysis, as a root cause analysis of incidents (RCA) or as an analysis of safety culture and error culture.

This ensures that collaboration works, processes run reliably, incidents and errors are avoided and employee motivation is maintained. In this way, we protect people and the environment from harm and protect your company from economic losses and damage to its image.

Root Cause Analysis (RCA)

Successful organisations learn from mistakes, incidents and accidents. In order to take the right measures, the causes must be identified. A well-founded analysis of the causes and contributing factors (root cause analysis, RCA), which covers the entire spectrum of human, technology and organization, helps here.

We support companies in the planning and implementation of RCA and accompany them until the measures have been successfully implemented. Together with the client, we look for effective solutions. This enables us to minimize risks efficiently and sustainably.

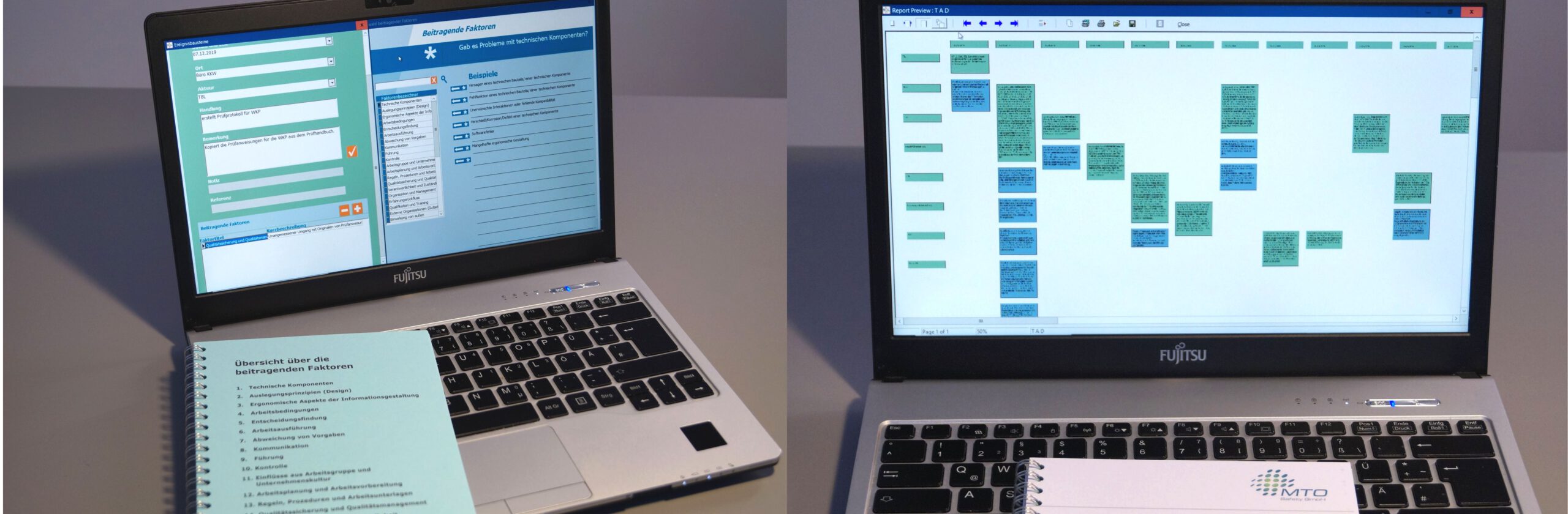

Our know-how is groundbreaking. Using the SOL Safety through Organizational Learning method developed by us, we systematically identify the causes and contributing factors.

Our know-how is groundbreaking. Using the SOL Safety through Organizational Learning method developed by us, we systematically identify the causes and contributing factors.

MTO Safety GmbH trains employees in the implementation of RCA. In two seminars that build on each other, the occupational science and psychological knowledge required to understand the interplay between people, technology and organization is imparted.

HTO Analyses with HAZOP

HAZOP analyses are an internationally established method for analyzing processes and technical systems. Human and organizational factors can also be integrated into a HAZOP analysis. HAZOP analyses are excellently suited to gaining insights into any remaining technical or organizational weaknesses in processes and technical systems.

Weak points in all areas of human-technology-organisation can be identified before they have an impact. This helps to avoid costly mistakes when introducing new processes and technical systems.

Safety Culture and Just Culture

We impart all the necessary knowledge to minimize errors and develop a positive safety culture. In our seminars and workshops, we provide employees and managers with the tools they need to avoid mistakes and prevent the negative effects of errors.

Managers are the key players in establishing a positive approach to mistakes. We work with managers to develop the necessary internal guidelines for communicating with employees and train them in helpful tools for dealing with mistakes.

Organizational Development

Thanks to our expertise in organizational development, we can effectively support our clients in implementing improvement measures. The PDCA cycle is then closed through the consistent evaluation of measures.